Measuring PVC pipe correctly requires understanding that PVC pipe sizing is based on nominal inside diameter (ID), not the actual outside diameter you can physically measure. This counterintuitive system means that a "4-inch" PVC pipe actually has an outside diameter of 4.5 inches, while its inside diameter is approximately 4.026 inches for Schedule 40 pipe.

The most reliable method to measure PVC pipe size is to measure the inside diameter directly using calipers or a pipe gauge, or calculate it by measuring the outside diameter and subtracting twice the wall thickness. However, for field identification, measuring the outside diameter and referencing standard sizing charts provides quick, accurate results.

Standard PVC pipe measurement methods

Inside diameter measurement (most accurate)

Use calipers or a pipe gauge to measure directly across the inside opening of the pipe. This method eliminates confusion about wall thickness variations and provides the true nominal size. Digital calipers accurate to 0.001 inches are preferred for precision work.Outside diameter method

Measure the outside diameter with calipers or a tape measure, then reference standard PVC sizing charts. This method works well for field identification when you cannot access the pipe's interior.Common outside diameter references:

- 1/2" nominal = 0.840" OD

- 3/4" nominal = 1.050" OD

- 1" nominal = 1.315" OD

- 1-1/4" nominal = 1.660" OD

- 1-1/2" nominal = 1.900" OD

- 2" nominal = 2.375" OD

- 3" nominal = 3.500" OD

- 4" nominal = 4.500" OD

Wall thickness considerations

PVC pipe wall thickness varies by schedule rating (Schedule 40, Schedule 80, etc.). When measuring PVC pipe diameter using outside measurements, you must account for these variations:Schedule 40 vs Schedule 80:

- Schedule 40: Thinner walls, larger inside diameter

- Schedule 80: Thicker walls, smaller inside diameter

- Same outside diameter for both schedules in matching nominal sizes

Different types of PVC pipe

Schedule Classifications

Schedule 40 PVC is the most common residential and light commercial application, suitable for cold water, drainage, and low-pressure applications. The thinner walls make it more economical but limit pressure ratings.

Schedule 80 PVC features thicker walls for higher pressure applications, industrial use, and situations requiring greater structural strength. The increased wall thickness reduces the internal diameter compared to Schedule 40.

Schedule 120 PVC represents the heaviest wall thickness for extreme pressure applications, though it's less commonly encountered in typical construction.

Application-specific types

DWV (Drain, Waste, Vent) PVC is specifically formulated for drainage applications and is typically white or cream colored. Wall thickness may vary from standard pressure pipe schedules.

Electrical Conduit PVC has different specifications than plumbing PVC, with smooth interiors optimized for wire pulling rather than fluid flow.

Cellular Core PVC incorporates a foam core between solid PVC walls, providing enhanced insulation properties for specific applications.

Types of PVC fittings

Pressure fittings

Socket fittings are the most common, designed for solvent welding with matching pipe. These include elbows (90°, 45°, 22.5°), tees, crosses, reducers, and couplings.

Threaded fittings incorporate NPT (National Pipe Thread) standards for connections to metal components or where disassembly might be required.

Flanged fittings provide bolted connections for large diameter applications or where frequent disassembly is anticipated.

DWV fittings

Sanitary fittings feature long-radius curves and specific angles designed to optimize drainage flow and prevent blockages. Common types include wyes, tees with cleanout access, and various bend radii.

Transition fittings connect PVC DWV systems to cast iron, ABS, or other drainage materials, often incorporating rubber gaskets or mechanical joints.

Specialty fittings

Union fittings allow pipe disconnection without cutting, critical for maintenance access in pressure systems.

Ball valves, gate valves, and check valves specifically designed for PVC systems provide flow control while maintaining chemical compatibility.

How to differentiate PVC from other materials

Visual identification

PVC pipe is typically white, cream, or light gray with a smooth, somewhat glossy finish. It feels lighter than metal pipe of equivalent size and has a distinctive plastic appearance.

ABS pipe is black and has a similar plastic feel but different chemical composition. ABS is often used for drainage applications and has slightly different joining requirements.

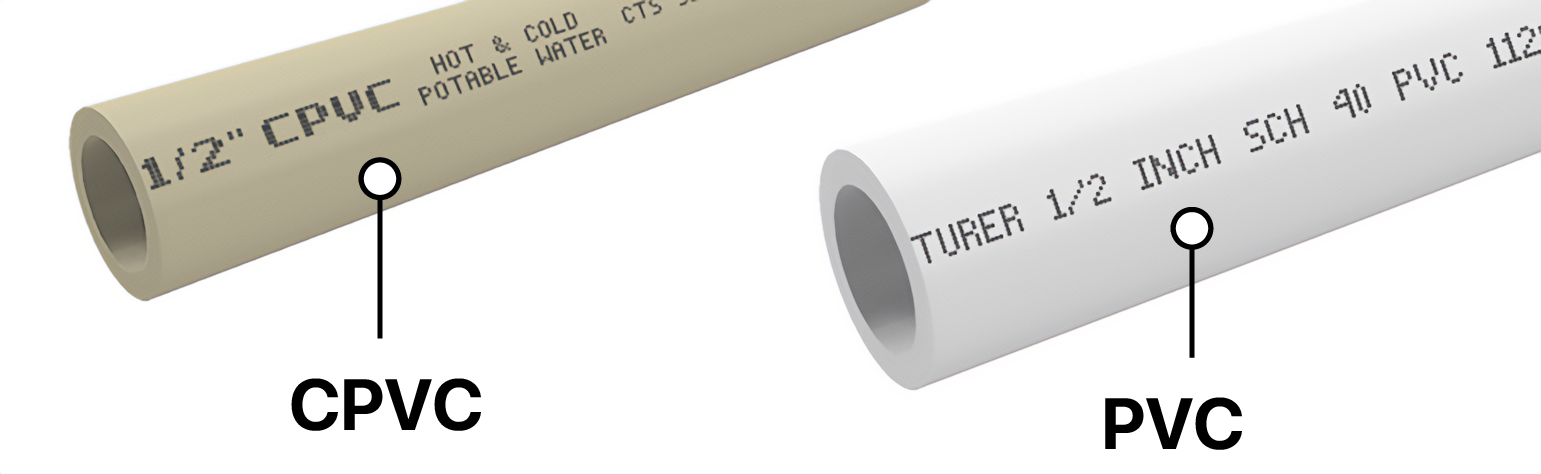

CPVC (Chlorinated PVC) is typically cream or light tan colored and is designed for hot water applications. It has higher temperature ratings than standard PVC.

Physical testing

- Temperature resistance: PVC becomes soft and pliable when heated moderately, while metal pipes conduct heat rapidly. CPVC maintains rigidity at higher temperatures than standard PVC.

- Sound test: Tapping PVC produces a hollow, plastic sound distinctly different from the metallic ring of steel or copper pipe.

- Flexibility: PVC has slight flexibility, especially in smaller diameters, while maintaining structural integrity. Metal pipes are rigid with no flexibility.

Chemical compatibility

PVC is resistant to most acids, bases, and salts but can be damaged by certain solvents and petroleum products. This chemical resistance helps differentiate it from metal pipes that may show corrosion or from other plastics with different resistance profiles.

Professional measurement best practices

- Documentation standards: always record both nominal size and actual measurements, along with schedule rating and application type. This documentation proves invaluable for future maintenance and expansion projects.

- Tool selection: Invest in quality measuring tools appropriate for your typical applications. Digital calipers, pipe gauges, and comprehensive sizing charts eliminate guesswork and reduce errors.

- Verification methods: When in doubt, cross-reference multiple measurement methods. The combination of inside diameter measurement, outside diameter comparison, and wall thickness calculation provides definitive pipe identification.

Understanding how to measure PVC pipe size accurately ensures proper fitting selection, code compliance, and system integrity. The investment in proper measurement techniques and tools pays dividends in reduced callbacks, improved system performance, and professional credibility.

Sources & Additional Reading

Primary Technical Standards

- ASTM D1785 - Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe

- ASTM D2665 - Standard Specification for PVC Plastic Drain, Waste, and Vent Pipe and Fittings

- NSF/ANSI 14 & 61 - Drinking water system components and health effects

Industry Organizations

- Plastics Pipe Institute (PPI) - Technical reports and comprehensive sizing charts

- Uni-Bell PVC Pipe Association - Technical resources for PVC pipe specifications

Manufacturer Technical Resources

- Charlotte Pipe - Industry-standard technical data sheets and specifications

- JM Eagle - Comprehensive pipe specification guides

- IPEX - Technical documentation for PVC systems

Code and Regulatory References

- International Plumbing Code (IPC) - Installation and sizing requirements

- ASME B36.10M - Pipe dimensions and tolerances